Step 1) First decide what is to be the top powered speed on your proposed vehicle. Usually this is set by government regulations and/or safety considerations.

Step 2) Second, decide the approximate actual tire outside diameter (O.D.).

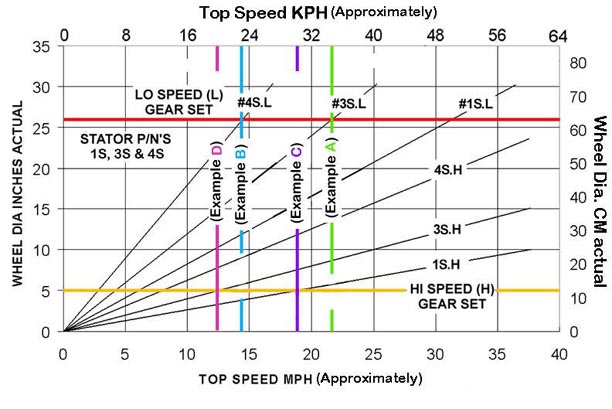

Step 3) Third, you can now use the following graph to determine the particular gear set (H for High or L for Low) and stator winding option (#1S, #3S or #4S) combination that you need to get what you want for your particular application.

Example B) If for the above 26" wheeled bike you expected to use it in a hilly area or where the government regulations dictated a maximum of 15 mph, the #4S stator option with the low (L) speed gear set (#4S.L) would be the logical choice; as a bonus the lower top speed yields a proportionally higher torque.

Example C) For a 5" Diameter sporty kick scooter on mostly flat ground you might pick the #1S.H system to yield a top speed of about 18 mph.

Example D) For a 5" Diameter scooter wheel in hilly terrain with a heavier rider, the #3S.H option with a top powered speed of about 13 mph might be a more agreeable choice.

As you can see, with the aid of this graph you can readily determine the appropriate gear set (H or L) and stator winding option (#1S, #3S or #4S) combination to fit your application. If one of these options does not fit your application, please consult the factory and we will design one to your needs; normally this will require extra time and possibly some one time engineering change charges, but we will be happy to work with you.

Next: How to construct a complete hub motor part number to get what you need for your application.

Constructing a complete hub motor part number is simple and straight forward once you have determined the "stator no." and the "gear set" required for your application. To now get what you want, please read the following and answer the enclosed questions; wherever possible, we advise using standard listed "item" part numbers for quickest delivery and lowest cost:

1) The "Basic Series" here is called the "500W". This series draws a maximum of about 20 amps from its nominal 24 Volt battery pack or about 500 watts, hence the name "500W". This maximum current is limited by a resistor buried in the controller and the level of current was selected to yield an acceptable performance with reasonable vehicle range. We have successfully tested this system at twice this value and while the increased performance is exciting, the range is of course proportionally reduced. We can lower or raise this value for special applications, but this will require a special controller production run which will increase our costs; please consult the factory if you need this done.

2) Pleasetell us your choice of MOLDED (M), WIRE SPOKED (S) or BOLTED (B) wheel types.

3) How many spokes do you want? On wire wheels, 36 is standard for 20 to 28 inch diameters, while 28 is standard for 12-18 inch wheels. Molded wheels are typically solid (1 spoke) up to about 8 inches; 10 to 16 inch wheels have 3 spokes and larger wheels generally have 5 spokes. Bolted wheels are solid (1 spoke). Special spoke numbers are available, but will require a one time tooling charge and possibly a higher cost.

4) Do you require DUAL (D) for bicycle type vehicles or MONO (M) for wheel chair or golf cart type vehicles, style shaft mounting?

5) We need to know the actual tire outside diameter (O.D.) in inches. (Please note, tire and wheel manufacturers nominal size typically deviates greatly from actual tire O.D. which we need to determine acurate vehicle speeds.)

6) Do you want the "free wheel" (FW), a "disc brake" (DB) or "no" (NO) options?

7) Look at nearby model photos to determine the "subset number" (#530, #1100, #1125, #1150 or #1175) required for your application.

Having completed the above, you can now fill in the blanks and give us a complete hub motor part number for your application.

Using the above examples, these are the resultant complete Hub Motor Part Numbers:

Example A) 500W.S36D26.FW.3SL.1125

Example C) 500W.M1.D5.NO.1SH.530

Example D) 500W.M1.D5.NO.3SH.530